FIRST Robotics readies for STEAMworks season

“It’s only been 10 minutes and we have already made a mess,” announced freshman Amon Green at the start of another Saturday morning work session for the Greenhills Robotics Team.

“It’s only been 10 minutes and we have already made a mess,” announced freshman Amon Green at the start of another Saturday morning work session for the Greenhills Robotics Team.

This mess comes from cutting precision plastic parts with the team’s CNC machine, drilling axle holes into the robot’s frame, lubricating the custom gearbox assembly, soldering together the parts of the electrical control system, and sawing out different wood shapes that make up the competition field. Each newly created part means a different robotic subassembly is nearing completion. Every new part also represents an opportunity for a Greenhill’s student to learn a new technical skill, to use tools to turn 2D drawings into 3D objects, and to develop confidence with ‘making’ solutions to complex problems.

The Lawnmowers are into their fourth of week of the 2017 build season and all the team’s students, mentors, and parents are collaboratively working together to build a robot for this year’s competition in March. This year’s challenge, “FIRST STEAMWORKS” is themed to represent “two adventure clubs from an era in which technology relied on steam power to prepare their airships for the ultimate long distance race.”

The Lawnmowers are into their fourth of week of the 2017 build season and all the team’s students, mentors, and parents are collaboratively working together to build a robot for this year’s competition in March. This year’s challenge, “FIRST STEAMWORKS” is themed to represent “two adventure clubs from an era in which technology relied on steam power to prepare their airships for the ultimate long distance race.”

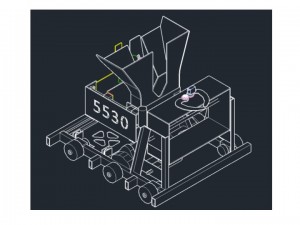

During a competition, four teams and their robots are tasked with delivering fuel (whiffle balls) to a simulated “steam boiler” to generate points that are documented in the form of accumulated kilo-pascals of steam pressure. Each robot also needs to deliver gears to a simulated steam powered “airship” that sits in the center of the playing field. Once each airship has enough steam and gears, it is time for the robots to climb aboard the ships by ascending a rope several feet off the ground. While this all seems complicated, Team 5530 is taking on the task with everyone working in subgroups that are focused on designing and building the key robot components. Each key component of the robot (the rope climber, gear placer, and ball shooter) is part of a system that is supported by computer code, an electrical infrastructure, and a chassis consisting of several powerful gearboxes. It truly takes a team to bring all of this together.

Lead mentor and Greenhills math teacher Alex Monte-Sano appears to gain energy by the minute working in a chaotic and messy shop, while also remaining calm and successfully managing an organized, student-centered team. The first week of the season focused on developing a shared understanding of and clarity for the game rules. This was done by mathematically modeling the different scoring options and clarifying ideas for strategy versus tactics during a competition.

Team discussions were busy, emotional, and noisy, but productive as Alex asked students to support their ideas with evidence from spreadsheets or simulations of game play. During week two the team prototyped different robot subcomponents to learn what ideas may work and what is possible to build. During these sessions, team members described what they did, what limitations they learned about, and what changes they thought were needed to create successful designs. Design critiques are exciting and energetic events that engage all members of the team – Alex Monte-Sano notes that it is important for the team to “reach consensus rather than vote” – so that everyone is satisfied with the team’s final decisions.

Team discussions were busy, emotional, and noisy, but productive as Alex asked students to support their ideas with evidence from spreadsheets or simulations of game play. During week two the team prototyped different robot subcomponents to learn what ideas may work and what is possible to build. During these sessions, team members described what they did, what limitations they learned about, and what changes they thought were needed to create successful designs. Design critiques are exciting and energetic events that engage all members of the team – Alex Monte-Sano notes that it is important for the team to “reach consensus rather than vote” – so that everyone is satisfied with the team’s final decisions.

For the next three weeks of the build season the team will be busy constructing and testing the robot in the basement shop, classrooms, the hallways, and the cafeteria– and Team 5530 is very thankful that our school community is so supportive of the team’s use of every aspect of the school campus. Leaving the basement shop at end of the Saturday work session, junior Zachary Brustman was asked how the electrical board was progressing.

“Messy, but in a good way,” he replied — a fitting closing statement for a successful day of robot building.

— Charles Dershimer, Greenhills science teacher